Home

Our Benefits

IMPROVE YOUR MANUFACTURING KPI’S

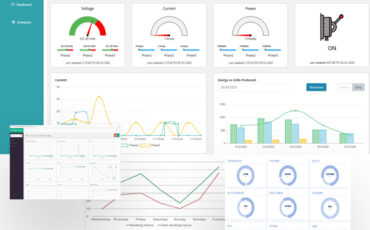

Linked Things’ Industrial IoT platform is designed for the management to receive relevant, actionable insights from the plant and floor directly in their boardrooms to support decision making, increase the profitability, reduce the costs and enhance the quality.

Our Benefits

IMPROVE YOUR MANUFACTURING KPI’S

Linked Things’ Industrial IoT platform is designed for the management to receive relevant, actionable insights lives from the plant and floor directly in their boardrooms to increase the profitability, reduce the costs and enhance the quality.

Linked Things

OUR PRODUCTS

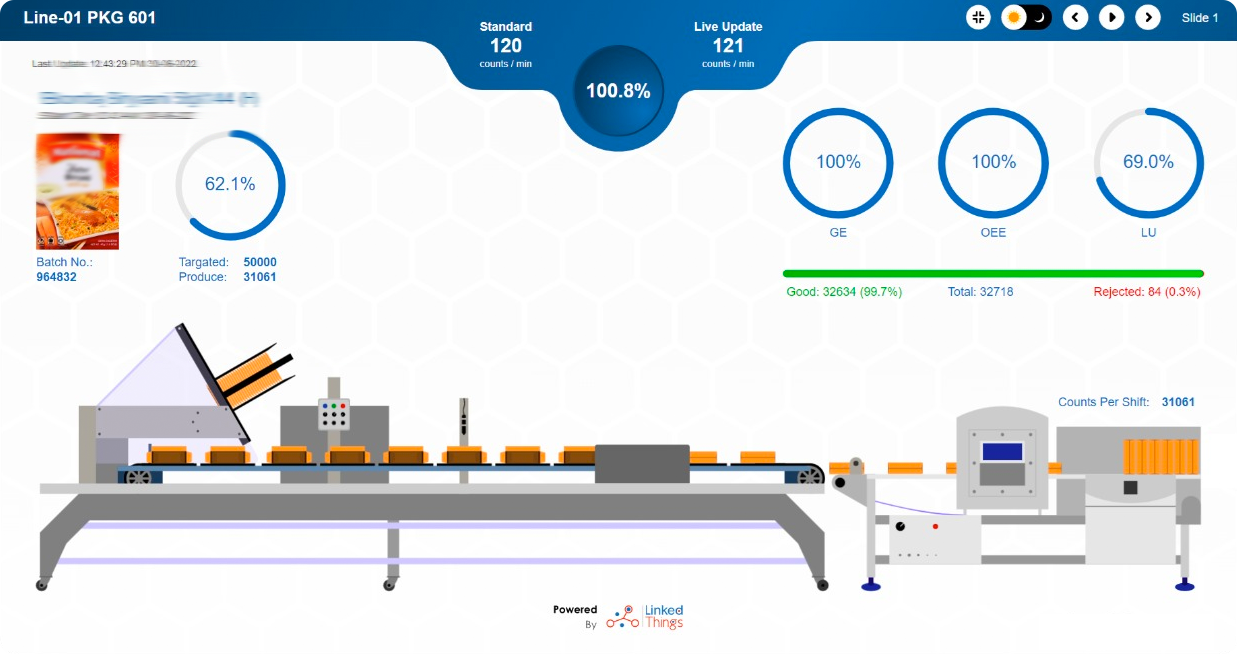

GE and OEE Calculations

GE and OEE are important KPIs in the manufacturing sector to determine the efficiency. We have deployed our sensors that monitor the production and down times and calculate GE and OEE in real time. The management has the line utilization and efficiency data whenever they need it to make a decision about increasing the production.

Tank Monitoring

We deploy sensors to monitor the inventory levels of water, edible oil, fuel oil, grains etc. The consumption pattern can be matched with the production and the data is useful for future planning. We also send the autogenerated messages to the suppliers to alert them to refill or the management to start planning procurement.

Predictive Maintenance

We monitor energy, hydraulic pressure, noise, temperatures and flows during production hours and predict maintenance requirements. This greatly reduces the down time, increases the lifetime of the equipment and helps in developing accurate production plan.

Quality Monitoring

Cold Chain is vital for food quality, a slight change in temperature over a period of time can compromise the quality and increases the losses for the food distribution companies. We have developed solutions that continuously monitor the storage at remote locations and alerts the staff not only about the food quality but about the freezers and cold rooms health status. This reduces the number of maintenance trips.

Proven Benefits

Food Processing Industry

We provide solution to monitor the temperature and humidity of silos and distribution vehicles so that the product quality is assured during transport and storage at various locations.

Proven Benefits

Cold Storage Monitoring

We provide solution to monitor the temperature and humidity of the cold storage and refrigerators. The information is available for remote sites such as retail outlet on a dashboard so that the management can monitor the quality of the perishable goods as well as predict maintenance requirements of the cold storage.

Proven Benefits

Food Processing Industry

Embrace IR4.0 with Linked Things’ Solution

- Supports Industry Transformation

- Rich Data Analytics and AI

- Easy Device Integrations

Proven Benefits

Predictive Maintenance

We monitor energy, hydraulic pressure, noise, temperatures and flows during production hours and predict maintenance requirements. This greatly reduces the down time, increases the lifetime of the equipment and helps in developing accurate production plan.

Proven Benefits

Advanced Manufacturing

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut eget aliquam purus. Nunc et neque lobortis, aliquet justo nec, egestas orci. Quisque malesuada nisi nec faucibus sodales. Maecenas massa risus, rutrum vitae risus eget, pretium mattis lorem.

Proven Benefits

Food Packaging Industry

We monitor product packaging machines for their up time, number of products packed, the line performance, log the reasons for downtime and prepare comprehensive report that helps companies increase their productivity and enhance the packaging quality.

Proven Benefits

Food Distribution and Storage

We provide solution to monitor the temperature and humidity of the storage such as distribution vans and refrigerators. The information is available for remote sites such as retail outlet on a dashboard so that the management can monitor the quality of the perishable goods as well as predict maintenance requirements of the sold storage.

Linked Things

Latest News

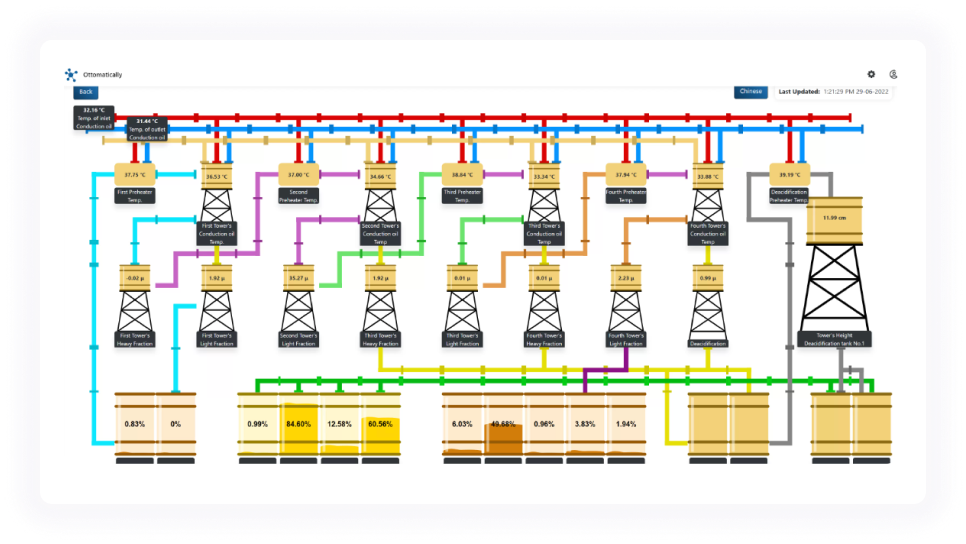

Linked Things delivers Digital Twin Solution to Jiangsu Xinsheng Oil Co Ltd

Jiangsu Xinsheng Oil Co Ltd (JXO) and Linked Things announced successful implementation of Digital Twin at the oil processing factory using Metaverse …

Revolutionizing Pakistani Banking

From 2016-18, Linked Things developed and provided months-long demos to five banks of Pakistan, HBL – Habib Bank Limited, National Bank of …

Gharibsons has signed up Linked Things

Gharibsons has signed up Linked Things for implementation of IIoT at its Rice Plant in Port Qasim. Rice processing requires continuous quality …

Our Customer’s Success Stories

Linked Things has been able to provide the perfect solution for air quality monitoring for our project in time and within our budget. The quality of the unit is of international standard and the UI shows what we would like to see in one glance and details.

Talk to an Expert

Start transforming your factory today

Call Us +92333-3794877

Call me Back fill this form

Linked Things

Blog & Articles

Smart Cities

One of the biggest question today for the Urban Planners and City Administrations are how to manage the cities in wake of …

The manufacturers powering productivity and sustainability

September 26, 2021The manufacturers of the Global Lighthouse Network—a World Economic Forum initiative in collaboration with McKinsey & Company —are setting tomorrow’s standards …

Implementing a digital transformation at industrial companies

Six building blocks can help industrial companies create a strong digital strategy and generate top value from digitization. Industrial companies have long …

Become an Expert in Manufacturing Efficiency

Subscribe to our blog newsletter.

+92 333 3794877 info@linked-things.com